- Home

- Fishing Line

- Nylon Fishing Line

- Fishing Leaders

Fishing Leaders: Why and When Should You Use Them?

Mention fishing leaders to a shore angler and he'll most likely

assume you're talking about shock leaders. Not an unreasonable reaction,

but he'd not necessarily be correct.

Why? Well, leaders fulfill a number of different functions, for example...

1. To absorb the high loads generated when casting heavy leads and lures.

2. To prevent a toothy predator from biting through the line.

3. To prevent a rough skinned customer from wearing through the line.

4. To minimise the visibility of the line.

5. To provide some stretch in the system.

Let's take a further look ...

Fishing Leaders for High Casting Loads

Surfcasters, particularly when using high-energy casting techniques like the pendulum cast, generate substantial loads in their rod and line. With this particular technique, the maximum load occurs halfway through the cast when the lead is travelling 90 degrees towards its intended destination - straight along the beach in other words.

Six ounces or more of spiked lead and attendant hooks hurtling at high speed in this direction would not be appreciated by sunbathers and the like. Embarrassing at best, potentially much more serious - so it's vital that this risk is eliminated.

Which is why surfcasters in particular use shock leaders, along with many other shore and pier fishermen - and boat anglers when up-tiding.

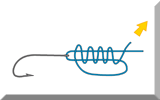

Shock leaders are made of nylon monofilament or fluorocarbon and must be long enough to have around six turns of the leader on the reel spool before the cast is made. Depending on the relative diameters of the leader line and the main line, the connection will be made by either a pair of Uni-Knots tied back-to-back or the Albright Knot.

| Lead Weight | Leader Strength |

6oz |

60lb |

8oz |

80lb |

4oz |

40lb |

The breaking strain of the fishing leader is related to the weight of the lead (or lure) to be cast; the breaking strain of the main line is of course irrelevant - and the heavier the weight, the greater the breaking strain of the leader must be.

The accepted wisdom is that the fishing leader (in lbs breaking strain) should be 10 times the weight of the lead (in lbs), as shown in the table here.

The knot can be a problem, particularly when the leader is at the upper breaking strain range. It can catch in the rod guides or get caught up in the coils of line on the reel. But there's a solution to this problem ...

Tapered Shock Leaders

These shock leaders are typically 70lb at the thick end (sinker end) and gradually taper to 18lb at the thin end to match your mainline. The benefit of course is that you're left with a much smaller joining knot that will whizz through your line guides with ease.

Low-Stretch Mono Shock Leaders

You might think that one of the properties for a shock leader is that it should be stretchy to absorb the shock loads, but for surf casting that's not what you want.

With a stretchy mono leader, a lot of the casting energy would be used in stretching the leader rather than powering-up the rod, which is why low-stretch, abrasion resistant mono line is produced especially for making up shock leaders intended for casting.

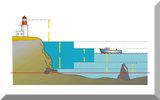

Fishing Leaders for Offshore Trolling

During the fight with the fish the line will come into contact with the fish's jaw, bill, gill plates, skin or fins, which are often abrasive and sharp. Your main line won't be capable of standing up to this kind of treatment, so you'll need a leader of more robust material than can.

Heavy monofilament or fluorocarbon line is best for this, which for offshore trolling could be 100lb breaking strain or more and as long as 25/30ft. Any kind of knotted correction between the leader and the main line will jam in the line guides, so another way must be found.

One way via is an Aussie swivel - which are small but immensely strong - and crimped connections. If you're using a rod with roller guides throughout, and they're large enough, this arrangement may allow you to wind the swivel through the guides directly onto the reel.

If this isn't possible, when the end of the leader arrives at the rod tip your fish will still be cruising smugly around some distance astern of the boat - and safely out of reach of the gaff. You only option now is to heave him in by hand, which can be an operation fraught with danger.

But there is another way ...

Wind-On Leaders

Put simply, a wind-on fishing leader is a length of mono line with a short length of dacron with a looped end attached to it.

This is constructed by inserting the mono up the inside of the dacron which is held there by friction. When tension is put on the dacron, it narrows down and grip the mono.

The looped end in the dacron is similarly formed by inserting its end back into itself. The end result is that you now have a mono leader with loop of dacron on one end of it.

There's rather more to it than that of course, but in a nutshell, that's what a wind-on fishing leader is.

A loop is formed in the main line, and the two loops hitched together. Ingenious, a reliable connection that will pass through your line guides with ease.

Wire Leaders

Fish like wahoo, barracuda, and shark of course, are renowned for the efficiency of their dentures, so while you might get away with a very heavy mono (300lb bs plus) leader, wire line would be safer.

For catch-and-release fishing, wire leaders should be short - not more than two feet or so - as otherwise they're likely to damage the body of the fish during the fight, which would be unacceptable.

The pros and cons of single-strand wire, nylon-coated multi-strand wire and multi-strand cable are set out in the table at the foot of this page.

Fishing Leaders for Low Line Visibility

Only one candidate for this - fluorocarbon.

These can be used with the Aussie swivel approach, or if that's not possible you could go down the wind-on route.

Fishing Leaders to Provide Stretch

Trolling with the ultra-thin non-stretch braid lines is very popular with sport fishermen, not least because it lets you use smaller reels and lighter rods.

But the non-stretch can work against you, allowing a hooked fish to shake the lure free - and the load exerted on your arms and shoulders is not something you'll forget in a hurry.

A stretchy mono leader is the answer, not the low-stretch variety used by surfcasters.

The Strengths and Weaknesses of the Various Types of Leader Lines

| Line | Strengths | Weaknesses |

|---|---|---|

| Nylon Monofilament | Inexpensive, supple, easy to knot or crimp | Poor resistance to teeth, large diameter compared to wire or cable of comparable strength |

| Fluorocarbon | Reputed to be virtually invisible under water, supple, easy to knot or crimp | Expensive, poor resistance to teeth, large diameter compared to wire or cable of comparable strength, |

| Single-strand piano or music wire | Inexpensive, resistant to sharp teeth, smaller diameter than monel or stainless for same strength | Subject to kinking, can only be connected by a haywire twist, not corrosion resistant so must be washed in fresh water after use |

| Single-strand Stainless steel wire | Inexpensive, resistant to sharp teeth, small diameter, better corrosion resistance than tinned wire | Not very pliable and subject to kinking, can only be connected by a haywire twist |

| Single-strand Monel wire | More pliable and less prone to kinking than stainless. Better corrosion resistance than stainless wire. | Can only be connected by a haywire twist |

| Single-strand Titanium wire | Flexible and kink resistant. Unequalled corrosion resistance and strength. Can be connected by Clinch and Albright knots. | Expensive! |

| Plastic coated multi-strand wire (1x7) | Inexpensive, resistant to sharp teeth, more supple than single strand wire, easy to handle, easily joined with crimps, small diameter | More visible than mono or wire, coating susceptible to teeth or abrasive surfaces, undetected corrosion inside coating. |

| Uncoated multi-strand wire (cable)(7x7) | Resistant to sharp teeth, more supple than single strand wire, smaller diameter than mono of comparable strength, easily joined with crimps, very durable | More visible than mono or wire |

Recent Articles

-

Sea Fishing Rods and Reels Must Be Compatible for a Balanced Outfit

Mar 08, 21 08:30 AM

A quality reel fitted to a quality rod doesn't necessarily make it a quality outfit. Your fishing rods and reels have to be properly matched if you're to get the best out of them, and here’s how -

Essential Lure Fishing Tips That All Saltwater Anglers Should Know

Mar 08, 21 04:51 AM

Which single lure fishing tip applies to trolling, jigging, baitcasting, spinning, fly fishing and any other branch of lure fishing? Well, it is the one at the top of this list -

Vital Jig Fishing Tips That You Really Cannot Afford To Miss!

Mar 07, 21 10:20 AM

Essential jig fishing tips to help you select the right lure for successful jig fishing, together with the techniques required to get the most out of your jig fishing outfit

New! Comments

Have your say about what you've just read! Leave me a comment in the box below.